Reduce Environmental Impact, Ensure Long-Term Economic Viability and Working Towards a Clean Environment

The Environmental and Economic Benefits of Repairing vs. Replacing Industrial Equipment

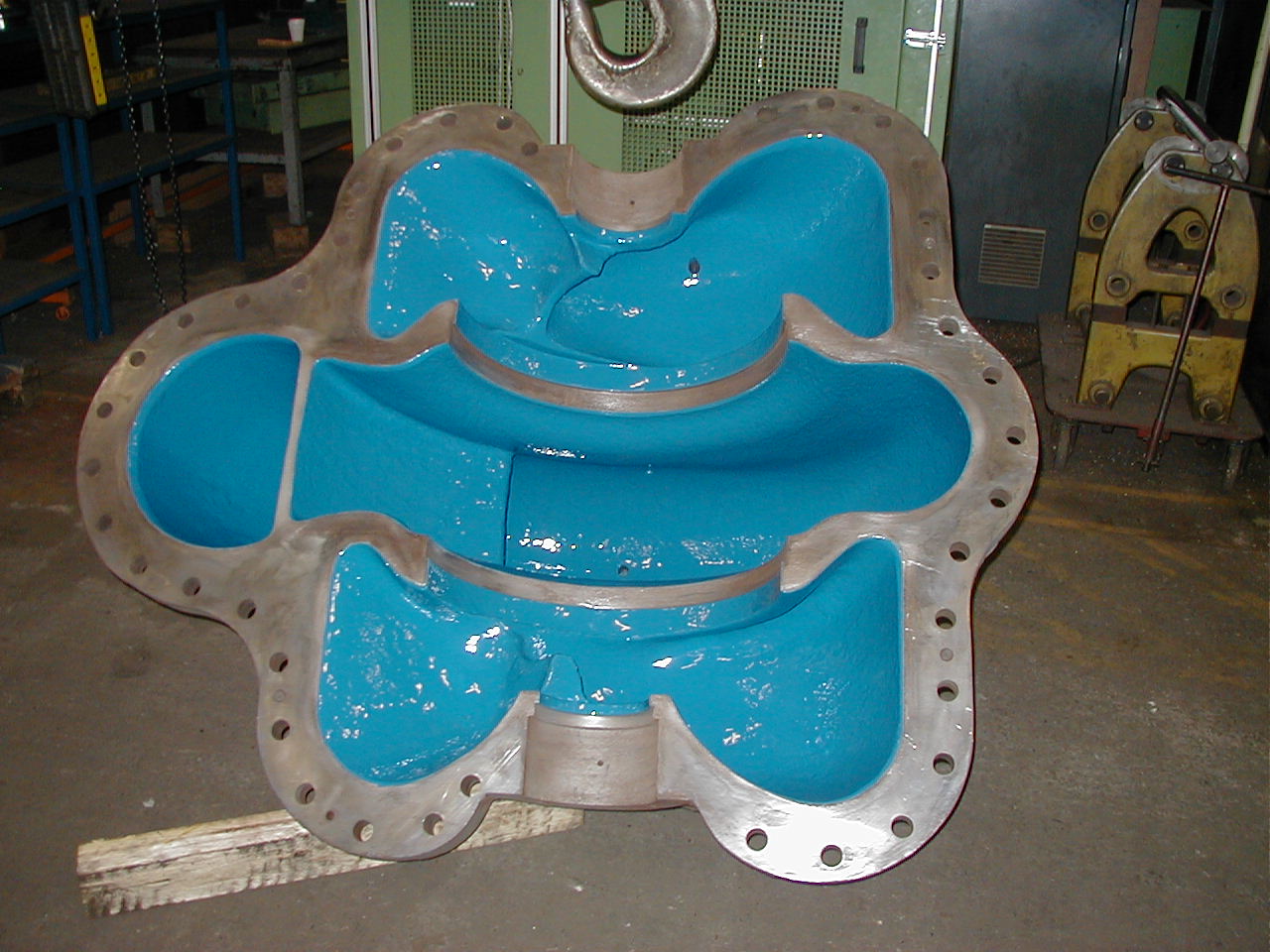

ENECON’s repair-don’t-replace philosophy conserves energy and reduces carbon footprints by repairing equipment, such as pumps and heat exchangers, which is inherently more environmentally friendly than replacement. From reducing operational downtime to conserving resources and lowering emissions, ENECON products and repairs offer practical and responsible alternatives to replacements.

Applications

Heat Refraction

Increase Pump Efficiency

Maintain Air Quality

Sustainability goals for repairs and maintenance primarily focus on reducing environmental impact by minimizing waste, optimizing energy efficiency through preventive maintenance, and extending the lifespan of equipment by proactively identifying potential issues through practices like predictive maintenance. ENECON and our network of global distributors specialize in identifying the following goals:

Energy Efficiency

Prioritizing maintenance practices that ensure equipment operates at peak efficiency.

Extending Equipment Lifespan

Maximizing the lifespan of assets through regular maintenance.

Preventive Maintenance

Implement routine inspections and maintenance schedules to catch potential issues early, preventing unexpected breakdowns and associated energy waste.

Waste Reduction

Minimize waste generation by repairing and reusing components instead of replacing them.

Predictive Maintenance

Leverage technology to monitor equipment health and predict potential failures, allowing for proactive repairs and reducing unnecessary interventions.

Regulatory Compliance

Adhere to environmental regulations and standards related to maintenance practices.

Recycling and Upcycling

Explore opportunities to recycle or repurpose old equipment parts when possible.

Staff Training

Educate maintenance personnel on sustainable practices and environmentally conscious decision-making.

Cost Savings

Sustainable maintenance can reduce operational costs by preventing equipment failures and minimizing downtime.

Improved Asset Reliability

Proactive maintenance strategies can enhance equipment performance and uptime.

Reduced Environmental Footprint

Minimizing waste and energy consumption has a more negligible ecological impact.

Positive Brand Image

Implementing sustainable maintenance practices can enhance a company’s reputation and appeal to environmentally conscious customers.

The Economic Advantages of Repairing Industrial Equipment

The Environmental Benefits of Repairing

How Repairing Aligns with Corporate Environmental Goals

Now is the Time to Think About Your Approach to Equipment Maintenance

Repairing industrial equipment isn’t just a practical choice—it’s a strategic advantage. It saves money, minimizes downtime, and extends the life of valuable assets. More importantly, it aligns with modern priorities, such as sustainability, regulatory compliance, and corporate social responsibility. By opting for repairs over replacements, businesses can reduce waste, conserve resources, and lower their carbon footprint, demonstrating that profitability and environmental stewardship can be mutually beneficial.

In an era where customers, employees, and investors demand greater accountability, repairing equipment sends a powerful message: your company is committed to innovation, efficiency, and sustainability. It demonstrates that you are not only prepared to meet the challenges of today but are also committed to building a responsible future.

Ready to save costs, protect your assets, and strengthen your environmental impact?

Please contact ENECON today to discover advanced solutions that will keep your operations running efficiently while supporting your long-term objectives.